#SMARTSCOPE MANUAL HOW TO#

It is not so good for repeatability with manual measurements, if there is not good fixturing and if there is a lack of understanding of how to set the light for the least variation by all of the operators. Most distributors/reps will be willing to demo the technology for you.ĭisclosure: I have no relations with any of the companies mentioned in my reply other that being a former or current user.Ĭlick to expand.Utilizing the correct fixturing and lighting control ( locking it into the program - should not be adjustable by the operator if set up correctly for best Gage R&R) it can be a very effective measurement device. Be sure that laser will work in your conditions and with your parts before investing in it. This was accurate enough for a machining shop, provided a great deal of flexibility and mobility, and was rather easy to learn. In one application I used was a laser scanner attached to the end of a FARO arm CMM. On the other hand laser scanning is good enough for some shop floor applications where quick 3-D checks need to be done. I have seen anf used GOM technology to scan a mock model of a car then scale it up to 1:1 for a 3-D model, and to scan stamping dies & parts for virtual assemblies. White light technology is highly recommended for reverse-engineering and high accuracy applications. I have used both white light and laser and there is a place for each. The environmental conditions and the part material can have significant impact on the accuracy of the laser scanned data. Regarding laser scanning, it is an inexpensive substitute for photogrametry (white light scanning), although the level of accuracy is not as good as with white light technology. Like other posters have indicated, a touch probe would definitely improve the capability and accuracy of the measurements. I believe it is a great tool for measuring flat parts with crisp, sharp edges though, and probably adequate for 3-D parts.

We were all getting different measurements on the same features and the same parts, depending on the light settings and camera focus. Three of us tried MSA studies a few times on one of these devices without success. I found the video CMM to be very unreliable (poor R&R) when it comes to measuring draft sides/shapes and blended edges in cast or molded parts.

#SMARTSCOPE MANUAL FREE#

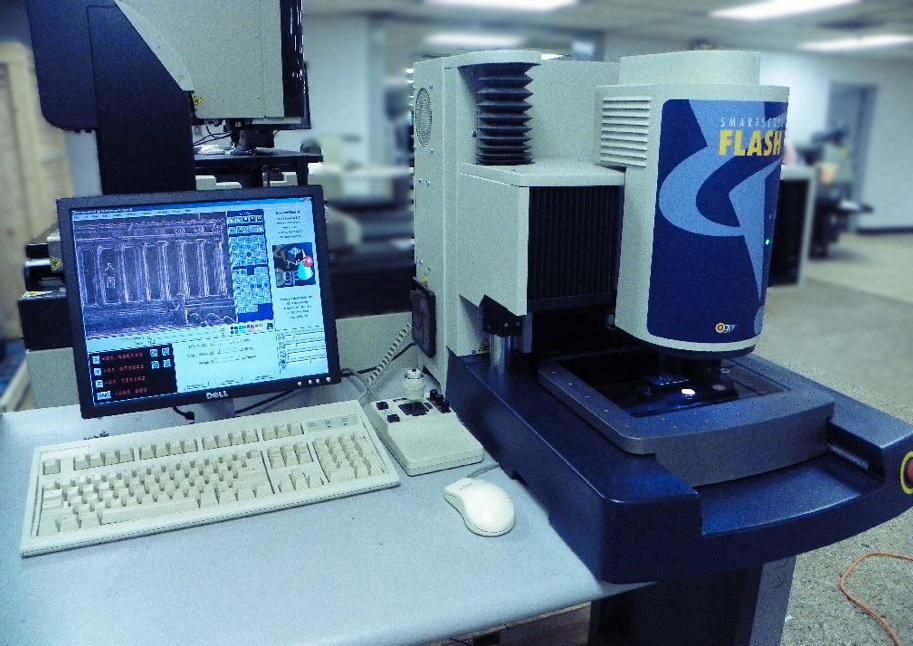

Please feel free to contact the authorized OGP Representative in your area to learn more, schedule an application study or a personal demonstration.ĭetailed information is available on the datasheet.I believe that a video CMM has it place but it is not a good over-all CMM substitute. Just add laser, touch probe, or micro-probing sensors and you’ll measure your most complicated parts in a single setup. Like all Flash systems, Flash 250 is fully multisensor capable. It’s ideal for a wide variety of manufacturing industries including metalworking, plastics, biomedical, electronics, automotive, aerospace, and more.Įvery SmartScope Flash 250 is multisensor capable.

#SMARTSCOPE MANUAL SOFTWARE#

Like all Flash systems, the SmartScope Flash 250 is equipped with OGP® Measure-X® metrology software and 12:1 AccuCentric® zoom optics. Its heavy cast base and rigid steel column provide metrology integrity so accuracy is maintained in real world environments. Its large 300 mm X travel makes it the system of choice for measuring critical dimensions of long parts on a benchtop machine. SmartScope® Flash™ 250 is a compact machine designed for easy access to the XY stage for maximum fixturing flexibility.

0 kommentar(er)

0 kommentar(er)